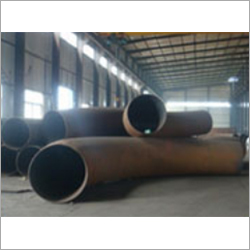

Carbon Steel Pipe Bends

Price 500 INR/ Piece

MOQ : 40 Pieces

Carbon Steel Pipe Bends Specification

- Tolerance

- 1% (Depending on Size and Standard)

- Temperature Range

- -29C to 425C (as per grade)

- Coating Type

- Black Paint / Varnish / Epoxy (as specified)

- Flexibility

- Rigid

- Sealing Type

- Metal-to-metal

- Connection Type

- Butt-Weld

- Bend Radius

- 1D, 1.5D, 2D, 3D, 5D, Custom

- Tensile Strength

- 415 MPa (minimum, material dependent)

- Yield Strength

- 240 MPa (minimum, material dependent)

- Diameter

- 12.7 mm 1219 mm

- Product Type

- Pipe Bend

- Material

- Carbon Steel

- Connection

- Butt-welded

- Shape

- Elbow / Bend

- Standard

- ASTM A234 / ANSI B16.9 / ASME SA234

- Surface Treatment

- Black Painted / Anti-rust Coating / Oil Coated

- Outer Diameter

- 1/2 inch to 48 inch (12.7 mm to 1219 mm)

- Section Shape

- Round

- Length

- Up to 6000 mm / As required

- Thickness

- Sch 20 to Sch XXS

- Color

- Black

- Usage

- Industrial, Oil & Gas, Pipeline, Chemical Plants

- Rated Pressure

- Class 150# 2500# (as per specification)

- Material Grade

- A234 WPB, A420 WPL6, A860 WPHY42-70 (Others on request)

- Application

- Conveying fluids & gases, Changing pipe direction

- Manufacturing Technique

- Hot Induction Bending / Cold Bending / Mandrel Bending

- Compliance

- NACE MR0175, PED, IBR (as required)

- Bend Angle

- 15°, 30°, 45°, 60°, 90°, 180°, Custom angles available

- Inspection

- 100% Radiography / Hydro Test / Third-party Inspection Available

- Lead Time

- Ready Stock / As per Quantity & Requirement

- Weight

- Varies as per size and wall thickness

- Customisation

- Available as per drawing or specification

- Packing Type

- Wooden Case / Iron Frame / Bulk

- Corrosion Resistance

- Yes, based on coating and treatment

- End Preparation

- Bevel End (standard) / Plain End

- Impact Test

- Applicable as per standard (optional)

Carbon Steel Pipe Bends Trade Information

- Minimum Order Quantity

- 40 Pieces

- Supply Ability

- 400 Pieces Per Month

- Delivery Time

- 2 Days

About Carbon Steel Pipe Bends

We are instrumental in supplying a wide range of Carbon Steel Pipe Bends, which are popularly known among our clients owing to their high build quality and ruggedness. These pipe bends allow systems to minimize pressure changes. Pipe bends are easy to implement within a processing system with the help of standard welding processes, flanges, and other connection methods. Due to their ruggedness and long operational life, we are seeing a huge demand for theCarbon Steel Pipe Bends in the marketplace.

Versatile Bend Angles and Customisation

Our carbon steel pipe bends can be supplied in standard angles ranging from 15 to 180, with the added flexibility of custom angles to suit any pipeline design. Customisation is available according to your drawings or application requirements, ensuring compatibility with complex network layouts.

Advanced Bending Techniques for Precision

Manufactured using hot induction, cold bending, and mandrel bending processes, these pipe bends meet stringent tolerances and structural integrity standards (1%). Guaranteed by comprehensive inspections like 100% radiography and hydro testing, reliability and quality are at the forefront of production.

Compliant and Reliable for Critical Applications

Meeting key industry standards and certifications including NACE MR0175, PED, and IBR, our pipe bends are suitable for high-pressure, corrosive, and demanding environments. With options for impact testing and anti-corrosion coatings, these bends are tailored for safe and sustained operation.

FAQs of Carbon Steel Pipe Bends:

Q: How are the bend angles for carbon steel pipe bends selected and customised?

A: Standard bend angles such as 15, 30, 45, 60, 90, and 180 are available. Custom angles can also be manufactured upon request, according to specific drawings or project specifications, ensuring the pipe bend fits your pipeline layout precisely.Q: What manufacturing techniques are used for these pipe bends?

A: Carbon steel pipe bends are produced using hot induction bending, cold bending, or mandrel bending. The chosen technique depends on the required bend radius, diameter, wall thickness, and the intended application, providing optimal strength and durability.Q: When is impact testing applicable for carbon steel pipe bends?

A: Impact testing is performed as an optional quality check, required when specified by relevant standards or during applications in low-temperature or high-risk environments. This ensures the bends meet toughness criteria for critical operations.Q: Where are carbon steel pipe bends typically used?

A: These pipe bends are widely utilised in industrial sectors including oil & gas, chemical plants, and pipelines for conveying fluids and gases. Their robust construction allows them to withstand high pressures, temperatures, and corrosive conditions.Q: What is the process for inspection and certification of carbon steel pipe bends?

A: Each bend undergoes rigorous inspection, including 100% radiography, hydrostatic testing, and third-party inspection, as required. Compliance with standards such as ASTM A234, ANSI B16.9, NACE MR0175 is ensured for guaranteed safety and performance.Q: How does the corrosion resistance of the pipe bends benefit users?

A: The corrosion resistance is achieved through various surface treatments like black paint, anti-rust coating, or epoxy varnish. This enhances durability, reducing maintenance needs and preserving the structural integrity over time in harsh environments.Q: What lead times can be expected for carbon steel pipe bends?

A: Lead time depends on the quantity, specifications, and whether the product is in ready stock or custom-fabricated. Immediate dispatch is possible for standard items, while custom orders will be delivered as per agreement.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry