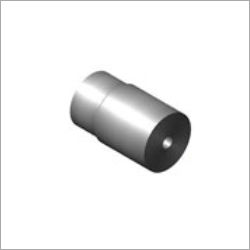

Socket Weld Bushing

MOQ : 40 Pieces

Socket Weld Bushing Specification

- Diameter

- 20 mm (Inner)

- Yield Strength

- 205 MPa (min)

- Temperature Range

- -20C to 400C

- Tolerance

- 0.05 mm

- Sealing Type

- Metal to Metal

- Flexibility

- Rigid

- Tensile Strength

- 515 MPa (min)

- Connection Type

- Welded

- Product Type

- Socket Weld Bushing

- Material

- Stainless Steel

- Connection

- Socket weld

- Shape

- Hexagonal

- Standard

- ASTM A182

- Surface Treatment

- Polished

- Outer Diameter

- 40 mm

- Section Shape

- Round

- Length

- 50 mm

- Thickness

- 4 mm

- Color

- Metallic Silver

- Usage

- Pipe Fitting Application

- Rated Pressure

- Up to 3000 PSI

- Material Grade

- SS 304/316

- Application

- Industrial, Pipeline, Chemical Processing, Oil & Gas

- Finish Type

- Mirror

- Test Pressure

- Hydrostatic Test Passed at 1.5x Rated Pressure

- Package Type

- Carton Box

- Weight

- 120 grams

- Hardness

- 150 HB

- Design

- Precision Machined

- Leakage Rate

- Nil

- Manufacturing Process

- Forged

- End Type

- Socket

- Corrosion Resistance

- Excellent

Socket Weld Bushing Trade Information

- Minimum Order Quantity

- 40 Pieces

- Supply Ability

- 400 Pieces Per Month

- Delivery Time

- 2 Days

About Socket Weld Bushing

Backed by a team of diligent professionals, we are actively engaged in supplying a wide array of Socket Weld Cap. This is a type of pipe fitting that is designed to cover the end of a pipe to stop the flow. It works the same as a cap. Due to its excellent corrosion resistance and distinct surface finish, this is sure to last for an extended period of time. Socket Weld Cap is available in a plethora of sizes and styles. The complete range of the weld cap can be purchased from us at a cost-effective price.

Precision Engineering For Demanding Applications

Engineered with high tolerances of 0.05 mm and mirror-polished for enhanced durability, the socket weld bushing offers unmatched reliability in industrial settings. Its forged stainless steel construction and hydro-tested integrity ensure top-tier performance even under extreme pressure and temperature conditions, making it a preferred choice for professionals in pipeline, oil & gas, and chemical processing sectors.

Superior Corrosion Resistance & Mechanical Strength

Fabricated from SS 304/316 and featuring a polished metallic silver finish, this bushing provides excellent resistance to corrosion, wear, and mechanical stress. With a minimum tensile strength of 515 MPa and minimum yield strength of 205 MPa, it offers lasting protection and stability, ensuring efficiency and safety in high-demand systems.

FAQs of Socket Weld Bushing:

Q: How is the Socket Weld Bushing installed in pipe fitting applications?

A: The bushing is installed using socket weld connections, requiring the pipe to be inserted into the socket end of the fitting and then welded around the outer edges to create a secure, leak-free joint. Professional welding ensures durability and proper sealing for high-pressure applications.Q: What materials are used for manufacturing this Socket Weld Bushing?

A: This bushing is forged from high-grade stainless steel, specifically SS 304 or SS 316, both known for superior corrosion resistance, strength, and suitability for demanding industrial environments.Q: When should I use a precision-machined forged bushing like this?

A: You should select a precision-machined forged bushing when you require tight dimensional tolerance, excellent corrosion resistance, and high strength under pressure, such as in pipelines, chemical plants, or within oil & gas operations.Q: Where is this Socket Weld Bushing commonly applied?

A: The bushing is widely used in industrial piping systems, chemical processing units, oil and gas installations, and other environments requiring reliable pipe connections and leaks prevention at temperatures ranging from -20C to 400C.Q: What is the process for ensuring the quality and integrity of the bushing?

A: Each bushing undergoes hydrostatic testing at 1.5 times its rated working pressure to verify structural integrity and leak resistance. Precision machining and mirror polishing further enhance its reliability and longevity.Q: How does the excellent corrosion resistance benefit piping systems?

A: Due to its SS 304/316 material and polished surface, the bushing provides robust protection against rust and chemical exposure, extending service life and reducing maintenance costs in harsh environments.Q: What advantages does the mirror finish offer in industrial applications?

A: The mirror finish not only improves the aesthetic appearance but also provides smoother surfaces that minimize fluid friction, resist scaling and deposits, and simplify cleaning within pipe systems.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Socket Weld Fittings Category

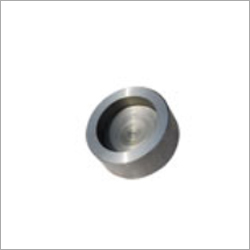

Socket Weld Cap

Minimum Order Quantity : 40 Pieces

Material : Stainless Steel

Tensile Strength : 515 MPa min (for SS304)

Connection Type : Butt Weld End / Socket Weld End

Socket Weld Elbow

Price 250 INR / Piece

Minimum Order Quantity : 100 Pieces

Material : Stainless Steel

Send Inquiry

Send Inquiry