Stainless Steels Pipe End Caps

Price 500 INR/ Piece

MOQ : 40 Pieces

Stainless Steels Pipe End Caps Specification

- Yield Strength

- 205 MPa minimum

- Coating Type

- Uncoated

- Tensile Strength

- 520 MPa - 620 MPa

- Flexibility

- Rigid

- Sealing Type

- Metal-to-metal

- Diameter

- 12.7 mm - 1219 mm

- Tolerance

- 0.5 mm

- Temperature Range

- -50C to 600C

- Connection Type

- Butt Weld

- Product Type

- Pipe End Cap

- Material

- Stainless Steel

- Connection

- Welded

- Shape

- Round

- Standard

- ASTM A403 / ASME SA403

- Surface Treatment

- Polished

- Outer Diameter

- 1/2 inch - 48 inch

- Section Shape

- Circular

- Length

- Customizable

- Thickness

- 2 mm - 20 mm

- Color

- Silver

- Usage

- Pipe Fitting End Closure

- Rated Pressure

- Up to 120 Bar

- Application

- Plumbing, Oil & Gas, Water Treatment, Chemical, Food Processing

- Material Grade

- SS304 / SS316 / SS316L

- Lifecycle

- Long-term Durability

- Corrosion Resistance

- Excellent

- Storage Condition

- Dry, Covered Area

- Impact Resistance

- High

- Finish Type

- Mirror / Matte

- Hardness

- Rockwell B80 - B90

- End Type

- Plain End

- Manufacturing Process

- Cold/Hot Formed

- Lead Time

- 7 to 15 days

- Density

- 7.98 g/cm³

- Packaging Type

- Wooden Box / Carton

- Heat Treatment

- Solution Annealed

Stainless Steels Pipe End Caps Trade Information

- Minimum Order Quantity

- 40 Pieces

- Supply Ability

- 400 Pieces Per Month

- Delivery Time

- 2 Days

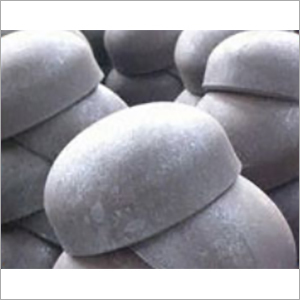

About Stainless Steels Pipe End Caps

We are instrumental in supplying a wide array of Stainless Steels Pipe End Caps, which are popularly known among our clients owing to their ruggedness and longevity. These end caps are made of the high-grade alloyed metal that is capable of standing tough impacts and rust. For this reason, these end caps do not degrade in quality or deteriorate in the long run. Stainless Steels Pipe End Caps are available in a plethora of sizes and styles at a cost-effective price.

Exceptional Corrosion Resistance

These stainless steel pipe end caps are crafted from high-grade SS304, SS316, and SS316L, delivering outstanding resistance to corrosionperfect for environments exposed to chemicals or moisture. Their polished surface enhances longevity, reducing maintenance and replacement costs over time.

Precision Manufacturing and Standards Compliance

Produced using advanced cold or hot forming techniques, each end cap adheres to ASTM A403 and ASME SA403 standards. With a hardness of Rockwell B80B90 and 0.5 mm tolerance, you can rely on consistent dimensions and superior mechanical strength for all industrial applications.

Customized Solutions for Diverse Industries

Available in a wide range of sizes, thicknesses, and finishes, these end caps are suitable for plumbing systems, oil and gas pipelines, water treatment plants, and food processing facilities. Their rigid structure and metal-to-metal sealing ensure robust closure and safety under rated pressures up to 120 bar.

FAQs of Stainless Steels Pipe End Caps:

Q: How do stainless steel pipe end caps provide excellent corrosion resistance?

A: These end caps are made from SS304, SS316, or SS316L stainless steel, all renowned for superior resistance to oxidation and chemical attack. Their polished surface further prevents rust and material degradation, even in harsh operating environments.Q: What is the typical usage of these pipe end caps in industrial applications?

A: Stainless steel end caps serve as reliable closures for pipe terminations in industries such as plumbing, oil & gas, water treatment, chemical manufacturing, and food processing. Their robust construction ensures safe containment of fluids under high pressure and temperature.Q: When can I expect delivery of custom-sized stainless steel pipe end caps?

A: Depending on your size and finish specifications, the lead time for most orders is between 7 to 15 days. Packaging options include sturdy wooden boxes or cartons to ensure safe transport and delivery.Q: Where should these end caps be stored before installation?

A: To ensure longevity and prevent premature corrosion, it is recommended to store the end caps in a dry, covered area, protected from moisture and direct weather exposure.Q: What is the manufacturing process for these stainless steel end caps?

A: End caps are formed using either cold or hot forming processes, followed by solution annealing for optimal mechanical properties. Each piece is then polished to achieve a mirror or matte finish, complying with international standards.Q: How does the metal-to-metal sealing benefit pipe systems?

A: Metal-to-metal sealing ensures a leak-proof closure, minimizing chances of contamination or seepage. This type of seal is highly durable, maintaining its integrity even during pressure fluctuations or temperature variations.Q: What are the mechanical strengths and dimensional tolerances of these end caps?

A: Each end cap features a tensile strength of 520620 MPa and a minimum yield strength of 205 MPa. The dimensional tolerance is maintained at 0.5 mm, ensuring precise fit and reliable performance in critical applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Pipe End Cap Category

Alloy Steels Pipe End Caps

Price 160 INR / Piece

Minimum Order Quantity : 40 Pieces

Rated Pressure : Up to 2500 psi

Application : other, Oil & Gas, Petrochemical, Power Plant, Water Treatment, etc.

Outer Diameter : 15 mm to 1200 mm

Product Type : Other, Pipe End Caps

Send Inquiry

Send Inquiry